This month I’d like to concentrate on some of the complications you are likely to encounter when selecting and applying a thermal interface material. I’ll also be looking a little more closely at thermal resistance, viscosity and vibration, and their effects on performance. Choosing a thermal management product is not just about ticking all of the correct boxes on a specification sheet. It’s a complex process that requires consideration of how to apply the product in accordance with production schedules and testing of the product in the final application. Selecting the right type of thermal management method for a particular electronic assembly and its predicted operating conditions is far from easy, and once selected, it is vitally important to ensure that the thermal management product continues to perform satisfactorily throughout the expected lifetime of the product. In order to establish this, the performance of the device or the thermal resistance between the device and the heat sink need to be measured again after accelerated aging or with environmental tests that simulate the real-world application conditions. Only this way can you be sure that the thermal management product chosen is really suitable for the job. So, without further ado, let’s explore how you can fully optimise your thermal management process using our trusted five-point question and answer format.

1) How do I ensure that my choice of thermal management material is the most appropriate one? What factors should I take into consideration?

Choosing a thermal management product must always take into account the application under production conditions because the thickness and uniformity of a thermal interface material can have a dramatic effect on the effectiveness of thermal transfer. A product tested under lab application conditions, therefore, may not behave in the same way as a material that is applied in production. For this reason, the most appropriate choice on paper might not be the best overall choice when taking in these additional factors.

2) What is thermal resistance?

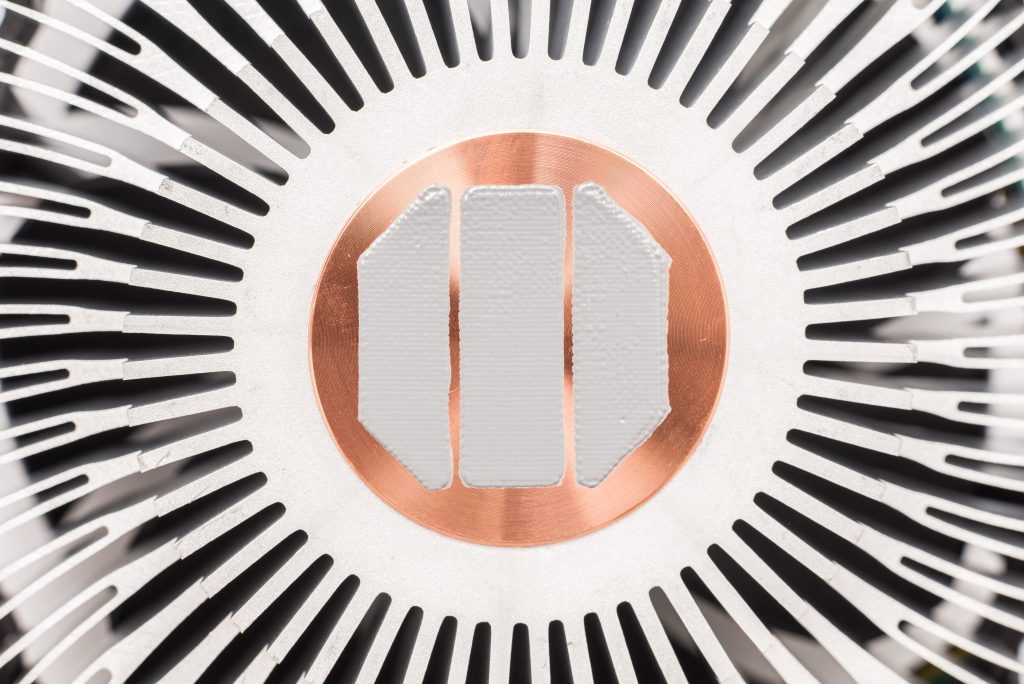

Thermal resistance doesn’t just rely on the bulk thermal conductivity alone, it considers the product’s performance in the actual use conditions by also factoring in the bond line thickness and the contact resistance at the two interface surfaces. The most common way to evaluate the performance of a thermal management product is to check the thermal resistance between component and heat sink, with and without the thermal management product applied. Another common method is to measure the device or component operating temperature, with and without the thermal management product applied.

3) Why does the viscosity of a thermal management material affect processing parameters and eventual performance of the product in use?

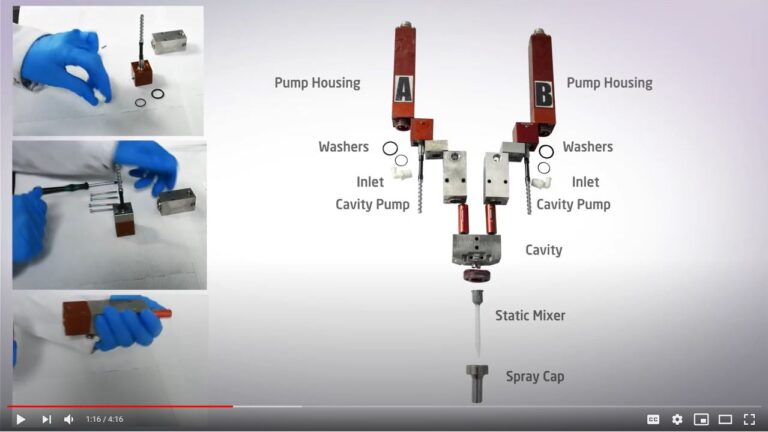

The initial viscosity of a thermal management material can impact the application method. For instance, with screen printing, the mesh size controls the thickness of paste applied. If the paste is too viscous, it may not spread very well over the screen and therefore, the desired thickness may not be applied. Similarly, with dispensing applications, if the product is too low in viscosity, it might spread too well and flow into unwanted areas.

When in use, the way a material responds to shear will indicate how the product may behave under changing temperature conditions, such as with the pump-out effect. If the thermal management material is shear thinning, it will reduce in viscosity with increasing shear. The effect of shear can occur between two surfaces, which expand and contract with changes in temperature, illustrated by their CTE. If you have large CTE values for the surfaces or big differences in CTE between the two surfaces, the effect of shear may impart a viscosity change in the product and hence effect it’s stability in end-use.

4) How significant a problem is vibration when considering the choice of thermal management material?

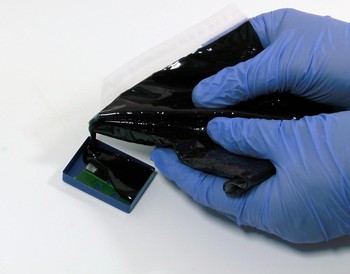

Vibration can be a significant problem in certain applications. Like the pump-out effect, vibration is a physical change that is happening in the surrounding environment and with such movement, a change in the position of the thermal management product may occur. This can lead to a reduced efficiency of thermal transfer. In gap filling applications, the effects of vibration can be much greater, especially if the product is a non-curing paste or putty. Gap filling applications generally have significantly more product applied in one area and therefore the movement from vibration can cause large shifts in the placement of the gap filling product if it is not contained by the structure of the PCB of casing. If vibration tests are required for the PCB, these tests should definitely be repeated with the chosen thermal management product present to ensure no significant changes are seen during the expected lifetime of the device.

5) Top 5 tips for success

One factor that I cannot stress the importance of enough, is to adopt the ‘test-before-you-buy’ approach. If a thermal management product is not tested before use, the end performance of your product might be very different to what you expected. The following points are essential for a successful thermal management process:

• Consider all influential external conditions – temperature, vibration, etc.

• Decide on the ideal production process for the volumes being produced.

• Look at the board design – for TIM applications, review if the interface gap can be minimised and ensure it is not excessively wide.

• Consider the materials present on the PCB/unit; are there any sensitive materials present? High CTE values?

• Test, test, test! Select the most suitable products based on the required heat transfer and take points 1-4 above into account – always test in end-use application conditions!

To enhance your reputation in the market, it is fundamental to ensure that the desired efficiency of heat transfer is achieved over the lifetime of your product. Deciding on the right choice of material and/or application technique can be challenging, however, companies like Electrolube have years of experience resolving customer thermal management issues and, as always, I strongly recommend you get some expert advice before you settle on any particular material or method, rather than try and attempt to resolve your thermal management queries in-house. I hope this month’s column will help you with your thermal management choices. Look out for my next column where I will elaborate more on thermal management issues. Please do get in touch in the meantime, if you have any suggestions for specific areas of discussion.