Make it with our expertise

Electrolube combines a wealth of knowledge, dedicated technical support team and three experienced R&D teams across three continents to find your specific applications tailored solution. With our unrivalled, very personal customer service across the globe you can be confident that you will be in the right hands. You can rely on our fully trained staff to be knowledgeable and up to speed with the latest technological developments. Having a named single point of contact helps to ensure that we work closely with our customers, solving problems in the most efficient way.

-

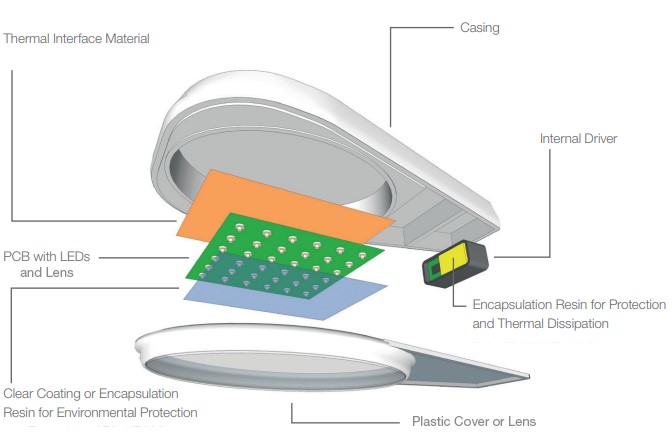

Conformal

Coatings -

Encapsulation

Resins -

Thermal

Management -

Contact

Lubricants -

Electronic

& General Cleaning -

Maintenance

& Service Aids

- Excellent technical support

- Strong research and collaboration

- Vast array of products and solutions

- Excellent customer service

- An additional department to any team

If our range does not quite meet what you are looking for, our technical support and research and development teams will work with you to solve your chemical problem and supply the perfect solution.

Make it our problem

Electrolube's product offering contains a number of successful products developed to meet specific customer needs:

Problem

The user in question (a large manufacturer of power distribution electronics) initially expressed an interest in Electrolube’s surface modifier materials due to longstanding and unresolved issues relating to coating coverage and connectivity. Their rationale for using a surface modifier coating as opposed to a conventional conformal coating was correct as the combination of required coating thickness (2µm) and very low film strength (abrasion resistance) can facilitate huge processing benefits.

Solution

Electrolube's current surface modifiers did not quite match all of the customer requirements, so FPC was specially developed for the customer.

FPC solved all the issues that the customer was having with the competitor product as well as providing several other benefits that the customer had not considered such as a UV trace to aid inspection and UL94 flame retardancy.

Problem

Customer required a thermally conductive resin capable of operating at high temperatures. Tested ER2221 which proved to be successful however the customer would prefer a red finish to blend in with the application design.

Solution

ER2222 was developed, based on ER2221 it shares many identical properties but once cured gives a red finish rather than the black of ER2221.

Problem

A manufacturer of green energy plants required a thermal management material for wind turbines. Electrolube products had built up a worthy reputation within the industry for performance and reliability, however the customer was looking for a more environmentally friendly product than was currently on the market.

Solution

The Electrolube R&D team developed a specialist version of HTCX in order to meet these demands. HTCX_ZF is a Zinc Oxide free thermal management material which offers the same levels of performance while minimising the hazardous elements.