Jade Bridges offers some more advice about which product type you should select and use based on a thorough appraisal of the assembly, its application and environmental limitations, and the problems that are likely to arise during production. She also offers two golden rules to help you avoid those costly mistakes.

Selecting the right type of thermal management method that will suit a particular electronic assembly and its predicted operating conditions is far from easy. There are a number of stages in the selection process that you should consider taking before you decide upon a particular material or, indeed, material format – be it paste or pad. In my latest piece on achieving effective thermal management of electronic assemblies, I shall revisit our trusted five-point question and answer format to bring some essential pointers forward, beginning with a few cautionary notes on ‘pain points’ – the occasional pangs of agony you will have to face during the decision making process.

What key ‘pain points’ are associated with thermal management products?

Well, where do I begin? There is a host of materials and methods out there to choose from, and they serve a variety of purposes depending upon the physical constraints of the application, its environmental considerations, the severity of duty, component layout, assembly geometry…….and so on.

When setting about choosing an appropriate product, perhaps a first question to ask yourself is: what data can be relied upon? Certainly there are some excellent technical datasheets out there which any self-respecting supplier will have taken great care to produce accurately and in good faith. But do you really know what thermal conductivity you will need, for example? And do you know just how much material will be needed in the interface between component and heat sink to achieve a thermally stable assembly?

Think about the practicalities – how you intend to apply the material: will it be manual or automated? And don’t forget those niggling details that tend to get overlooked – the operating environment conditions (which might cause pump-out, for example); migration of the interface material and its effects on the surrounding components or the materials used in the construction of the assembly, which are likely to include sensitive plastics, and special coatings. For guidance on all this, read on:

How do I avoid these pain points?

To answer this and the questions raised in the previous paragraphs, let me give you two golden rules which should at least get you on the right path to making informed choices.

Rule 1: by all means read through the technical datasheets but don’t just compare the values on paper. Get some product samples and see how they really behave in a real application. A good supplier will be more than happy to accommodate this type of request and some may even offer in-house test facilities to help you make the right decision.

I cannot stress enough the importance of this ‘test-before-you-buy’ approach. If a thermal management product is not tested before use, the end performance of your product might be very different to what you expected. If you value your reputation in the market, it is vital to ensure that the desired efficiency of heat transfer can be achieved and retained over the expected lifetime of your product.

Rule 2 – taking a cue from the property market, it’s all about application, application, application! Make sure the product chosen matches your production needs and don’t forget those rework requirements which will slant your choices towards specific material chemistries. Don’t be reticent in seeking advice; speak to your thermal management materials supplier about your key requirements, both in application and in final use, to ensure the best combination of properties are present in your final material choice.

How do I know that my thermal management choice is the best solution for the job?

The most common way to evaluate the performance of a thermal management product is to check the thermal resistance between component and heat sink, with and without the thermal management product applied. Another common method is to measure the device or component operating temperature, with and without the thermal management product applied.

As mentioned previously, it is vitally important to ensure that the thermal management product applied continues to perform satisfactorily throughout the expected lifetime of the product. In order to ascertain this, the performance of the device or the thermal resistance between it and the heat sink need to be measured again after accelerated aging or environmental tests that simulate the real-world application conditions. Only this way can you be sure that the thermal management product chosen is really suitable for the job.

Don’t forget, whatever your choice, you need to consider the application of the thermal management product and the volumes that will be needed for production. Make sure the chosen product also meets your needs in terms of ease of application and that its dispensing/application rate is compatible with production line speeds.

How do I apply a thermal paste?

Thermal pastes are designed to be applied as thin, uniform films. They should cover the entire surface area of the mating contact, with no excess. Any excess that is pushed out from the interface when, for example, the component to be thermally managed is brought together with its heat sink, should be removed. Apply too much thermal paste and it may cause issues with extrusion outside the interface boundaries, oil bleed and – most importantly – increased thermal resistance, resulting in reduced heat transfer efficiency.

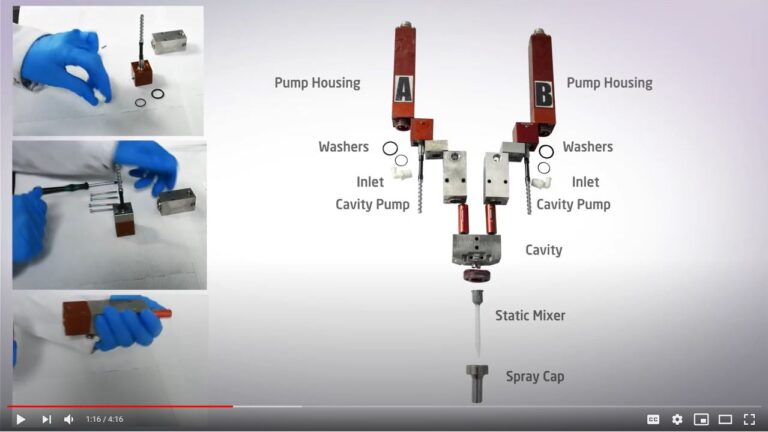

Thermal pastes can be applied via screen or stencil printing or by using specially designed dispensing equipment. In all cases, the correct amount of thermal paste should be calculated to ensure only the minimum thermal paste required is deposited at the interface.

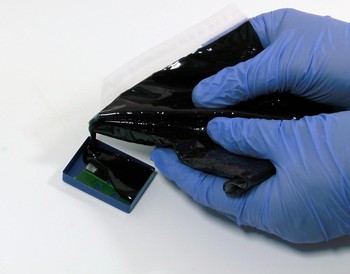

Why would I choose a gap pad over traditional thermal paste?

So far, I’ve concentrated on thermal pastes, which are essentially liquids of varying viscosities and supplied in several chemical types. Another method is to use gaps pads – sheet materials that can be pre-cut to the size and shape that is required. They are simple and easy to use, typically being applied manually to the surface, so there’s no requirement for mixing, preparation or curing stages. The answer really is that gap pads can be a viable solution, particularly for low volume, hand assembly type operations.

So, hopefully, the foregoing will have suggested some easier routes through the minefield of thermal management material choices! Look out for my next column where I hope to shed a little more light on thermal management issues.