IoT, otherwise known as the Internet of Things, is a platform enabling embedded devices connected to the internet, to collect and exchange data with each other. Devices can begin to interact and work with each other, even learning from each other’s experience as humans do. The potential for the IoT and connectivity is endless, as everyday objects can connect and share intelligence and knowledge. Some current examples deploying IoT include one of the earliest examples of this technology, wearable technology, which has now extended vastly to encompass the healthcare sector, sports, athletics, and even implantable devices. Some other areas where IoT applications are experiencing rapid growth include the Smart Home, Health Care, Smart Cities, Smart Grids, Agriculture, connectivity within vehicles and Industrial Automation. In this month’s column, I will be exploring how resin chemistries can be incorporated by design engineers facing ever increasing new challenges from IoT applications.

MacDermid Alpha Electronics Solutions brand Electrolube, has many protection solutions for sensors used in IoT. Recent collaborations have included protecting a sensor within a fuel storage tank monitoring system. The sensor can detect phase separation, where water contamination causes a gasoline only layer at the top and an ethanol/water layer at the bottom of the tank. The sensor can detect this out of specification gasoline at its earliest stages of formation as well as measuring the degree of phase separation. The fuel storage tank monitoring system is also used to monitor fuel storage tanks for inventory tracking purposes, leak detection and water accumulation. Such accuracy requires the use of water-level sensors. Electrolube was approached by a manufacturer to protect the water level sensor. Electrolube’s two-part silicone potting and encapsulating resin, SC4003E, is designed for the protection of electronic devices from challenging environments and answered all the protective requirements specified by the manufacturer. SC4003E cures at room temperature and provides excellent resistance to water and chemicals, it is also flame retardant and has excellent high temperature properties.

What Makes UR5118 Suitable For IoT?

New technology is generally targeted at making our lives better. IoT is all about connecting physical devices, wirelessly, using sensors and software to exchange data and facilitate connections and communication.

There are loads of exciting examples of how IoT is helping to improve and sustain the world around us, not just make our day to day simpler. Smart connected homes can prevent unnecessary energy use with the ability to turn off lights, or control boiler activity remotely. Smart sensors are even more sophisticated, able to measure air quality and send alerts when pollution levels are high, a great way to drive communities and governments to combat rising pollution levels and bring health benefits to asthma suffers. Smart farming involves monitoring the external environment and agricultural processes, to automate a response, this makes it possible to reduce the amount to water used to hydrate crops reducing wasteful processes and focus on the value-added inputs. So, what makes polyurethane resin UR5118 suitable for IOT applications?

Firstly, UR5118 provides excellent electrical insulation across a wide operating temperature range, required for long-term performance. The resin has a low dielectric constant (relative permittivity), most IoT communication takes place in blocks of the radio frequency spectrum, a low dielectric constant is essential to ensure the resin does not interfere with the RF signal. It has a high toughness offering protection from physical shock and vibration and is hard to tare. It has excellent resistance to sea water; the low water absorption makes it an ideal choice for ruggedizing sensors both above and below the surface. All in all, the perfect candidate for IoT devices.

Are Potting Compounds and Encapsulation Resins the same?

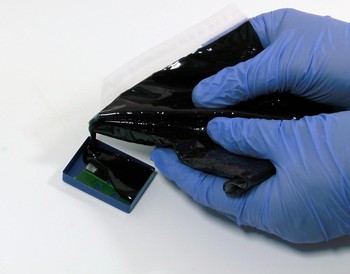

The terms ‘potting’ and ‘encapsulation’ are used interchangeably. Both describe a simple process of covering a component to provide protection from the threats posed by the external environment. In the case of protecting electronics, typically a one- or two-part resin is poured in its liquid state over components of a circuit board. A curing mechanism takes place, this could be a chemical, thermal, UV or a moisture cure process, to form a solid resin to sufficiently ruggedize the electronics.

However, if you want to be technical, there is a slight difference between ‘potting’ and ‘encapsulation’ processes.

‘Potting’ describes the scenario where the electronic component, for example PCBA, is housed within a unit, a ‘pot’. It would normally be the case where the ‘potting compound’ is poured in to fill the entire housing unit, once cured, the entire system; the electronic component, cured potting compound and the housing unit become the finished component.

‘Encapsulation’ on the other hand, describes a process where the electronic component and cured encapsulation resin are removed from the housing (the pot), and placed into a different assembly, the housing is merely there to act as a temporary mould to pour in place the resin.

Are Resins Prevalent In The Growing World Of Wearable Technology?

Wearable devices are becoming more and more popular, utilising IoT technology, these gadgets are leading us to a better-connected lifestyle. Typically, these devices rely on sensors and use RF signals to transfer information, connect and communicate with another device. The main challenge for wearable devices, is ensuring the delicate sensors and components can continue to function in the environments they are subject to. Consider a smart watch, the sensor must survive several physical interactions, the watch is worn, moved, experiences physical shocks and maybe stretched. Usually exposed to several elements, like water, chemicals, or oils, especially for fitness fanatics tracking all their extreme activities. Clearly these devices must be protected to ensure reliable performance. Electrolube encapsulation resins can provide the solution.

UR5041 is a two-component, high performing polyurethane resin system and finds uses in wearable technologies including smart-watches and other fitness trackers. UR5041 has a low dielectric constant and so does not interfere with signal communications, it is tough with high tear resistance, suitable for sub temperature uses and has exceptional resistance to seawater. The perfect solution for a range of challenging environments including marine and seawater swimming.

Electrolube’s UR5634 is a two-component, semi-rigid, optically clear polyurethane, it finds uses in many wearable devices and functions to protect display screens and LEDs, the resin is formulated to resist yellowing when exposed to UV light – particularly beneficial to wearable devices exposed to direct sunlight. This low-hazard resin is weather resistant and impervious towards lots of fluids.

IoT is an evolving market, where the various performance criteria for components is constantly changing to keep up with the latest developments in technology. Encapsulation resins capable of dissipating heat away from hard working components clearly add value to a variety of applications. With multiple research and development facilities, MacDermid Alpha Electronics Solutions and Electrolube are well positioned to quickly respond to these market changes. Our Technical Support Engineers are on hand to support design engineers select the best encapsulation resin for their unique applications. I hope this has been of interest to those of you involved in IoT and helps make life a bit easier for those who are responsible for making the decisions on protecting components and circuitry. Look out for my next column, where I will be exploring resin systems in more detail.