I’m really not trying to second guess you, but suspect that you are probably thinking; “What do a group of chemists at Electrolube know about the intricacies of design engineering?” Well… generally not much – but not all of us are Chemists; I myself studied Mechanical Engineering.

At Electrolube, what we do know about are problems and we understand that problems rarely stem from a single issue or discipline. This is why we have developed a whole range of different chemical solutions over the years, rather than staying with the single group of Contact Lubricants as per the start of the company back in 1941. What’s the point of solving an issue in one area, if we are unable to resolve other problems that may crop up?

So… the question stands; how can we, a chemical solutions manufacturer, help you to overcome design engineering obstacles?

We Know That The Solution May Not Be Chemical….

One of the more challenging projects I’ve worked on was with a well-known company making communication devices. This project displays how our experience and multi-angular approaches to problem solving surpasses that of our competitors.

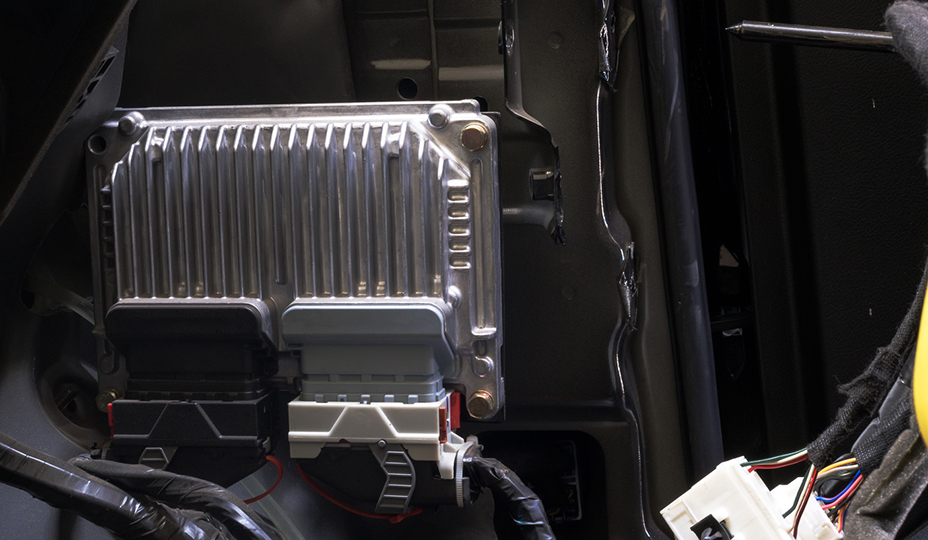

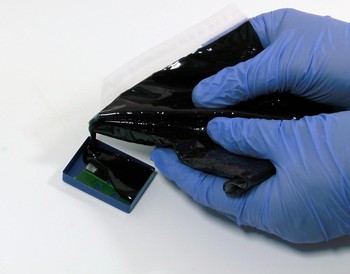

This client wasn’t making simple, cheap devices to be used in everyday life; they needed to build high-value, custom designed units to be used in a hazardous environment. As such, their units needed to be potted to protect the units from the stringent environmental conditions in which the unit would be placed. We knew this project was a race against time; after all, they had approached a number of other Encapsulation Resin manufacturers with their project.

Due to the nature of the application and stringent testing regime, the required material properties were very specific. Therefore, gathering all the information I could about the project was critical; even the slightest oversight could turn into failure, due to the nature of the application. Both the testing and the materials had to be faultless.

After careful thought, I shortlisted a few of our possible Encapsulation Resins for the job. We began the initial testing, as did a competitor who was also vying for the contract, and the results weren’t looking good for either of us. All units eventually failed after HALT testing (Highly Accelerated Life Testing).

“We couldn’t pinpoint a chemical problem, but noted some slight issues with the customer’s unit design.”

I didn’t let this negative step faze me, and took it in my stride. Experience with other projects has taught me that missing even the most miniscule detail of an application can have a dramatic effect on how a resin performs. Maybe I had missed something?

Unlike most other technical sales professionals, I have a daily stream of communication with my in-house technical support team and the multiple development chemists who make it up. I shamelessly picked the brains of my colleagues, and after analysing the situation as a group, we found we couldn’t pinpoint a chemical problem, but noted some slight issues with the customer’s unit design. The position and spacing between the PCB and the unit meant that during their thermal shock testing, all the resins tested exhibited some form of adhesion loss.

By this point, our rivals who we were competing over the contract for had lost interest; they were stuck for ideas. I, however, returned to the client with a fresh perspective, and suggested a few simple design changes which solved the issue – and all of our resins then successfully passed their tests. The problem was rooted in the design of the PCB board all along!

Needless to say, we successfully won the contract to supply that day and were awarded the contract over our competitor. Our technical support team’s breadth of experience in problem-solving, along with expert knowledge in various fields and applications means we’re well equipped to approach a problem from multiple angles.

I daresay our client would still be aimlessly looking for a chemical solution had we not stepped in to save the day!