Last month, the technical team at Electrolube looked at the pitfalls of potential contaminants and best mixing practice for two part Encapsulation Resins. This month, we are going to look at some of the pain points with mixing resin packs and air bubbles, what can go wrong and why, as well as examine some of the key differences between Conformal Coatings, Encapsulation Resins and Potting Compounds. The ultimate aim here is to help design engineers with informed decisions and ultimately help to increase the reliability and lifetime of electronic circuitry.

Extending lifetime and improving the performance of devices is essential to a brand’s reputation; no one appreciates a product recall, or worse still, a product failure. Encapsulation Resins are an excellent way of protecting electronic circuitry, however, there are some excellent Conformal Coating alternatives on the market too. We will elaborate further to help dispel any confusion. For instance, we have created the 2K coatings range, offering a very high level of protection with the application ease of a coating. This has been a great success in applications such as automotive where protection in harsh environments is critical.

So, let us take a closer look at five critical factors affecting encapsulation resins:

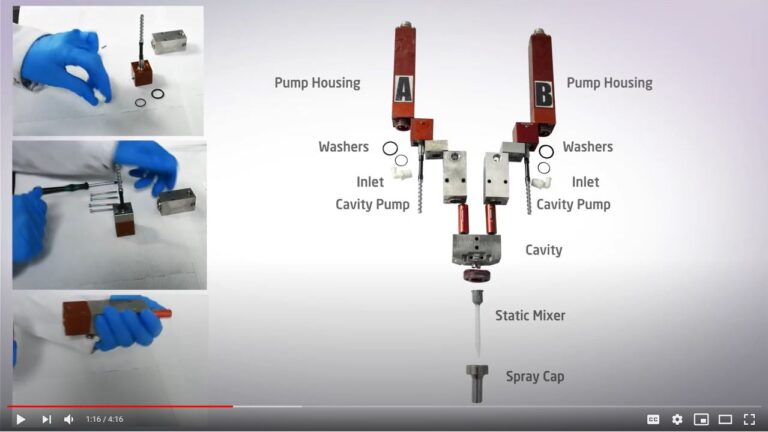

1) Mixing a resin pack, what can go wrong and why?

Last month we discussed how to mix resin packs effectively, and an instructional video can be found here: Link

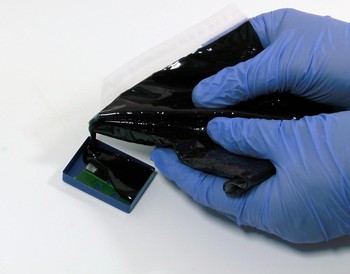

Mixing of the resin is a vitally important part of the process, for example if the resin is not fully mixed when it is dispensed it can cause problems with the cure, which in turn can affect the overall properties of the resin.

In the case of filled resin systems, some sedimentation might have taken place over time, so it might take a little more mixing to ensure that the fillers are distributed evenly throughout the resin. In the case of optically clear resins, when first mixed, the resin will appear hazy. This is perfectly normal and the haziness will disappear as the material reacts.

2) What are the consequences of having air bubbles trapped in Encapsulation Resins and does this impair performance?

Air bubbles can have a number of effects upon the performance of the cured resin. Depending upon the number and distribution of the bubbles, the actual thickness of the polymer layer applied will be decreased, hence the level of protection will also be reduced, particularly against chemical attack.

If there are air bubbles next to components, wiring or tracks, then particularly when high voltages are applied, corona can build up inside these voids and ultimately destroy the components or wiring. Voids also act as a weak point for thermal and physical shock, which can lead to the resin cracking in service.

2) What are some key differences between Encapsulation Resins and Conformal Coatings?

The most noticeable differences are the methods of application (aerosol, conformal coating spray equipment, manual spray gun and brushing for coatings, compared to mixing and dispensing equipment and resin packs for resins). Thickness of application (<100 microns for Conformal Coatings, <500 microns for thick coatings and >500 microns for resins) is also a key factor. Approval ratings are also part of the mix as Conformal Coatings are often approved to UL746, whereas for Encapsulation Resins it is very much dependent upon the application). As a result of the Conformal Coating thickness, they occupy less space and have a low increase in overall weight compared to Encapsulation Resins. There are Conformal Coatings and Encapsulation Resins based on epoxy, polyurethane and silicone chemistries, but there are also acrylate, acrylic and parylene coatings, which do not have a direct resin equivalent. 99% of resins are 100% solid systems, so have low or no VOC’s released during curing, whereas many coatings are solvent based. It is important to note that Electrolube also offers two component (2K) and UV curable acrylate systems that contain 100% solids. 2K coatings, in particular, can be applied thickly, without cracking during thermal shock testing and enable a greater degree of component lead coverage to be achieved, resulting in improved performance during thermal shock, powered salt-spray testing, MFG testing and condensation testing (traditionally gruelling test regimes, commonly used during automotive qualification campaigns). The 2K series are fast curing, VOC and solvent free.

4) Why would I choose an Encapsulation Resin instead of a Conformal Coating?

The choice between an Encapsulation Resin compared to a Conformal Coating is usually as a result of application specifics. If the unit involved is to be subject to long-term immersion in various chemicals, subject to continuing thermal and/or physical shock cycling, then a resin is generally preferred. Also, if there are a number of large components on a PCB, it is generally better to use a resin to encapsulate these than to coat them. Further consideration should also be given if the unit is to be used in a situation where it is not easily accessible or if a long continuous service life is a requirement, in which case a resin would be recommended to provide the extra protection and durability needed.

5) Are Encapsulation Resins and Potting Compounds identical or are there any differences?

There are no differences between the two in terms of the resins used, but there is a difference in how the resin is required to perform. An encapsulation resin will totally cover the PCB and the components and can act as the protective support structure, while a potting compound is used to fill a housing or enclosure containing the PCB and components. Therefore, an Encapsulation Resin will adhere to the PCB and the components, and its’ outer faces will act as the primary barrier to protect the unit. However, a Potting Compound has to adhere not just to the PCB and components, but also the housing. In this case, the differences in CTE (coefficient of thermal expansion) between all the materials used can become a critical factor, as the resin will be subjected to different rates of expansion and contraction due to the materials concerned, as well as its own CTE. This can put a resin under extreme stress and, over time, lead to failure.

I hope the points covered this month have been helpful and please do feel free to reach out to Electrolube with any questions you would like to ask. Electrolube also has a large number of technical resources available for your interest.