As the LED industry has grown exponentially over the past few years, it is fascinating to observe the varying designs and uses of LED units. This growth has led to a requirement for units to perform in increasingly challenging environments. Ultimately, this results in increasing demand for a range of reliable products with which to protect and prolong the life of the luminaire.

As an example of the varying nature of the LED industry, Electrolube has produced case studies including Automotive exterior lighting, Swimming pool lights, under-foot street lights and even stadium lighting for the European games.

For this months’ blog, I decided to focus upon another LED oriented case study and more specifically a general and widespread application; namely street lighting.

A Brief Overview:

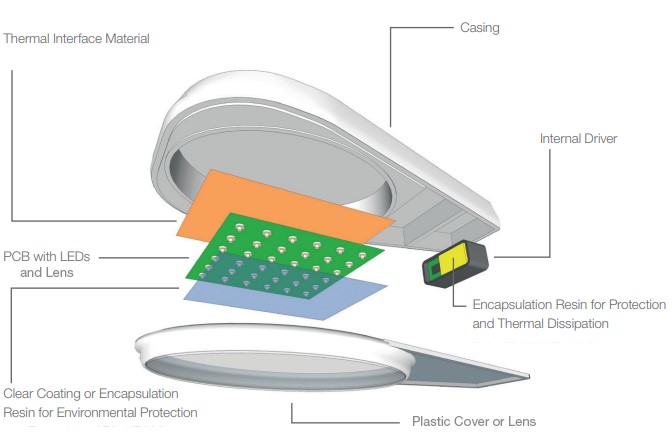

Regardless of the manufacturer or design, an LED street light will compose of several key elements; a lens (to disperse or focus the light), the LED luminaire, PCB, driver and the housing to contain the components. Depending upon the manufacturer specifications, the elements are protected with electro-chemicals such as encapsulants or thermal management in various configurations.

Specifics of the Customer Problem:

In this particular case, a leading Indian manufacturer of street lighting and high-bay luminaires had been experiencing problems with the attachment of individual lenses to the elements of multiple LED arrays. The function of these lenses is to scatter or focus light from the arrays, as required, and whilst some of the lenses were held in position by fasteners, most were secured in place with a locking mechanism. The locking mechanism was perfectly adequate when the LED was in situ, but unfortunately, it tended to loosen during transportation, resulting in a detachment and damage to the array.

The manufacturer originally tried using cyanoacrylate adhesives as an alternative means of attaching a lens, but this solution was rejected as whilst the cyanoacrylate produced a good bond, it also caused stress cracks to the lens. Additionally, fumes emitted during the application process also posed a health hazard to operatives.

As a second step, the manufacturer decided to try some epoxy adhesives that had been utilised in other areas of production. The first epoxy used produced a good bond but produced a yellowing effect when fully cured, ruining the desired aesthetic effect of the unit. The second epoxy trialled took too long to cure, ultimately delaying the tight production schedule.

A fast curing, clear adhesive was deemed the only solution, and aware of Electrolube’s reputation for solving seemingly intractable manufacturing problems for a variety of electronics manufacturing clients, the customer approached Electrolube India, confident that the team would be able to suggest a suitable product.

Assessment:

The team and I assessed the customer’s needs, which specified manual mixing and dispensing; a good bond to the polycarbonate lens and a clear finish with no effect on the optical properties of the lens. Unusually, this application did not require full encapsulation of the lens but we quickly decided that Electrolube’s UR5634 polyurethane resin would more than meet the all of the requirements of this application while also providing some additional benefits.

UR5634 is a two-part, semi-rigid aliphatic polyurethane resin which exhibits excellent adhesion to a wide range of plastics including polycarbonate which the lens was made from. Specifically formulated to be optically clear with a transparent finish, UR5634 maintains a high level of clarity and is eminently suitable for LED encapsulation and potting applications. These special properties define UR5634 as the resin of choice for aesthetically decorative LED luminaires. This polyurethane encapsulant also offers an exceptionally fast cure time once mixed and is formulated with less hazardous components than other resins on the market, offering improved operator safety. Additionally, as an encapsulant, UR5634 offers a high degree of flexibility, which protects the LED from vibration. This gives improved protection of the unit during transport, allowing resolution of the initial problem. UR5634 also offers several benefits unspecified in the customer brief such as protection from thermal cycling, (experienced as the units are exposed to the intense heat of the day). The monsoon season in India also produces some dramatic environmental conditions against which the units would be protected with this encapsulant.

Testing and Results:

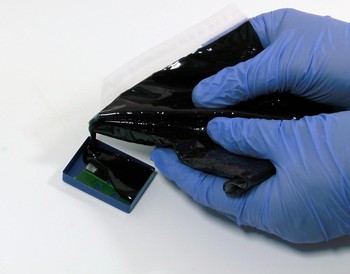

We quickly sent across samples to the customer in our standard 250g pack format – pre-measured packs, ready to mix for ease of use. Initial tests proved to be successful with the resin offering the expected excellent adhesion and optical clarity plus ease of use.

The only concern from the customer was that the 250g packs were slightly large for the volume per-unit required which affected the accuracy of the bead size and resulting in some material wastage.

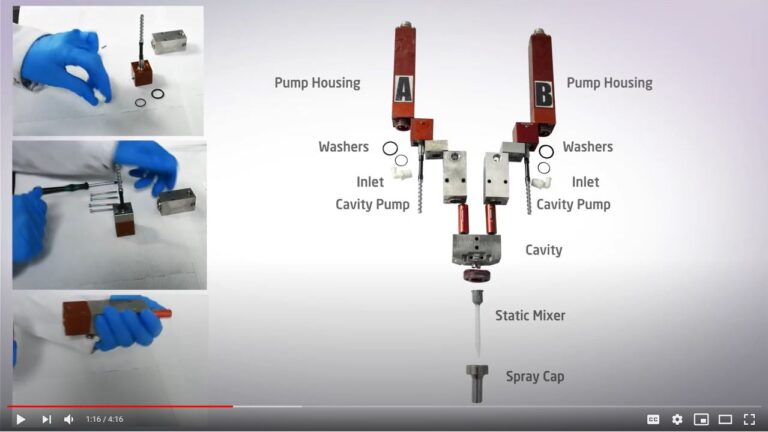

To resolve this we offered a fully bespoke solution for the customer by looking at alternative options for supplying the resin in a smaller volume while maintaining the ease of mixing and application provided with the 250g pack. We concluded that to get the most accurate results, a pre measured 50ml twin syringe cartridge with a static mixer nozzle would still provide the operator with easy mixing and allowing more accurate application for the delicate LEDs. This had the additional benefit of further minimising the operators contact with the resin.

The solution also provides complete flexibility for the customer should they wish to embark upon future design changes.

Conclusion

As ‘The Solutions People’ we are beginning to earn quite a reputation for our problem solving capabilities in addition to being able to offer some of the worlds’ finest electro-chemical products. India has a particularly dynamic market with a rapidly expanding electronics industry and the value-added service offered by Electrolube is key. Our LED customer was delighted with the solution that we offered them and we are confident that our problem solving capabilities and commitment to excellent customer relations will ultimately secure our growing position as the leading provider of electro-chemical products and applications expertise in the LED industry.