Conformal coating developments are far from static and must always be one step ahead of the technology curve if they are to serve the industry’s ever-changing needs. Here, Electrolube’s Phil Kinner chooses five trending customer queries on the subject of conformal coatings – from their properties, through that all-important selection process to the method of application. He also provides some insight into the special requirements of manufacturers applying conformal coatings to miniaturised electronics.

In my previous blog, I touched upon the environmental impact of conformal coatings and how the industry is striving to find new formulations – principally water-based, solvent-free materials – that have minimal environmental impact. For my present column, I shall return to the Q&A formula that my colleagues have adopted in past issues and attempt to answer current and trending queries from our customer base on coating properties, selection and application. In addition, I hope to shed more light on the coating problems posed by electronics miniaturisation, which is certainly exercising the minds of designers and production engineers from a growing cohort of customers in the consumer electronics sector. So, without further ado, here are ‘five of the best’ questions that frequently arise when we enter preliminary consultations with our clients.

In an ideal world, what combination of properties would a coating exhibit?

The performance requirements of conformal coatings continue to become ever more challenging as electronic assemblies are subjected to increasingly hostile operating environments. The ‘perfect’ conformal coating would retain high elasticity at both high and low temperature extremes, and would maintain its properties at high temperatures with no out-gassing. It would also provide an excellent barrier to moisture, both in terms of humid environments and where there is a risk of liquid water splash. It would be highly resistant to solvents and corrosive gases, but be easy to remove when repairs or modifications need to be carried out. Ultimately, the perfect coating would be intelligent, self-applying and, of course, free of charge – but then that’s a whole different ball game!

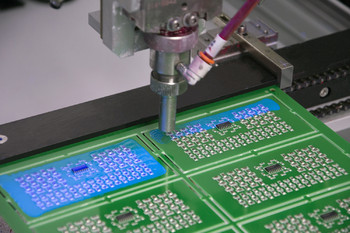

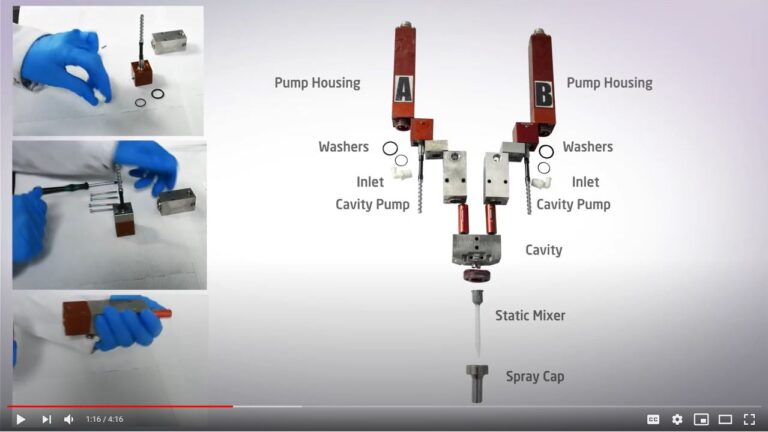

On a more serious note, an ideal coating should also be solvent-free and, as I pointed out in my previous column in this series, there has been some progress in this area, with a new range of innovative VOC-free, fast-curing, high performance two-part conformal coatings now available for application by selective coating. The 2K, solvent-free selective coating process is a new and enabling technological breakthrough that allows all the benefits of 2K coating materials to be realised

How does the design of the board impact upon the choice of coating material?

The design of the board doesn’t directly affect the choice of coating material, although it will determine which application methods can be used to apply the coating. Certain materials – for example, moisture curing, or UV curable materials – are difficult to use in a dip process due to the material curing prematurely, so it could be said that the choice of coating is indirectly related to the board design.

The use of single component UV curable materials has grown significantly over the past decade, with rapid cure yielding productivity benefits for many. However, the current single part UV materials often suffer cure issues when applied to boards containing tall components, which shadow the exposure to UV light and necessitate out-of-focus cure heights, reducing light intensity and degree of cure. Consequently, a secondary cure mechanism must be introduced into UV curing – typically a moisture-activated or heat-activated mechanism.

What electrical properties are typically required of conformal coatings?

Conformal coatings form a protective, insulating layer. The most common electrical parameter tested is the Surface Insulation Resistance (SIR), a measurement often taken before and after coating and subsequent exposure to harsh conditions to determine the long-term insulation performance of the coating. The coating should also have high dielectric strength, the minimum level required being determined by the inter-track separation and the potential difference between adjacent tracks.

The Dielectric properties are an important consideration where the signal integrity of the circuit is concerned. Conformal coatings applied to such circuits must not affect signal integrity and here the coating’s dielectric constant and dielectric loss are parameters that must be taken into account when making a material selection and determining the coating thickness. Other than this, dielectric strength, dielectric breakdown and dielectric withstand are commonly measured and reported properties that enable designers to ensure sufficient spacing between components or, more normally, to determine how much closer components can be spaced than without coating materials applied.

The application method of coating materials is a key consideration – how is the best method defined?

There isn’t necessarily a ‘best’ method to apply a conformal coating. The application method chosen for a particular assembly will depend upon which existing equipment is available to the manufacturer, the coating processes in use, take time (the average time interval between the start of production of one unit and the start of the next) and the design of the assembly. This includes those areas of the circuit which must be coated and those which must not (connectors, switches and so on).

The ‘best’ application method would ensure that each board to be coated receives coating coverage on all required metal surfaces at a sufficient thickness to afford protection against the environment. These requirements will change from board design to board design, and environment to environment and invariably they need to be tested and verified ahead of the production run.

How has the trend for miniaturisation affected the development of coatings?

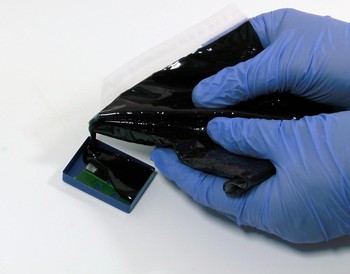

The trend towards miniaturisation is most evident in consumer electronics and has led to the development of ultra-thin coating materials with thicknesses of less than 12 microns. This, in combination with internal gasketing and better case design, has enabled the production of vastly more water-resistant mobile phones and other handheld devices.

In more traditional applications, such as aerospace and automotive, there is a double issue of finer pitch components (reduced space between conductors) and a need to reduce weight, resulting in less protection being afforded by the board’s housing. The impact of this is that coatings need to function more as a primary mitigation strategy against the environment. As a result, the performance requirements of these coating materials have increased dramatically, especially with regards to condensation resistance.

Hopefully, the foregoing has answered some of your questions about conformal coatings and how they are developing to meet modern manufacturing and circuit design needs. Look out for next month’s blog and if you have any questions about conformal coatings for us, please send an email to info@electrolube.com.