Newly manufactured and cleaned printed circuit boards will generally perform well electrically, but performance will quickly deteriorate due to adsorption of atmospheric moisture, contamination of the surface with airborne ionic material, electrostatic attraction of dust to the surface, condensation etc. In order to avoid these problems boards for more demanding and high specification applications are often conformally coated as the last stage of manufacture.

Conformal coatings are normally applied to circuit boards by dipping or spraying, typically at a thickness of 20-50 micron, although conventional silicone and other specialist coatings can be applied at up to 100 micron thickness. In prototyping or small volume production coatings may be applied by simple brushing. By preventing contamination of the surface, they help to prevent corrosion of conductors and solder joints and also reduce dendritic growth between conductors – this leads to long term improvement in performance by reducing erosion of conductors and also minimising the occurrence of short circuits. The use of conformal coatings is particularly important in automotive under-bonnet applications and also military, aerospace and industrial applications, particularly in safety critical areas.

It should be remembered that conformal coatings do have their limitations however. Any contaminants present on the surface before conformal coating will be sealed in by the operation and may cause long term problems – such contaminants might include fingerprints, flux residues and moisture and other atmospheric pollutants. Boards should always be cleaned and dried before conformal coating to obtain optimum long term performance. Even when using so-called no-clean fluxes, cleaning boards before coating will usually improve long term performance and reliability. Conformal coatings are not generally very effective in offering protection in applications that involve significant exposure to liquid water (as distinct from water vapour), especially when it contains ionic material. In such applications it will generally be necessary to protect the board by potting or encapsulation – this will almost invariably offer a much higher level of protection that can be obtained by use of conformal coatings. Potting is generally more expensive than conformal coating, and also carries a significant penalty as far as the weight of the component is concerned.

The ideal conformal coating will have performance requirements that include good electrical properties, low moisture permeability, good chemical resistance and mechanical durability. It will adhere well to all the board materials such as the basic board material, solder resist, copper and solders and also the numerous materials used for the components used to populate the board. In many applications good thermal properties are important, with flexibility retained at low temperatures and a high retention of mechanical properties at elevated temperatures. Typical tests that might be carried out on conformally coated boards include long term damp heat testing, resistance to salt spray and thermal shock and thermal cycling performance. Chemical resistance tests and flammability tests may also be carried out where appropriate.

The ideal conformal coating as far as processing characteristics are concerned will be one-part (two-part systems are very inconvenient to use), have a long bath life, and a low curing or drying temperature and short drying time. Various drying times can be quoted – touch dry time is when the coating is tack free to the touch, through dry time is when all solvent has evaporated throughout the coating layer and cure time is when the coating has fully cross-linked. Viscosity should be easily adjustable so that it can be optimised for the equipment being used. Where solvent based systems are being used, a high solids content will minimise solvent emissions and reduce any environmental concerns. Equipment that enables use of higher viscosity materials will help minimise any environmental problems.

One deficiency of conventional liquid conformal coatings is that they do not cover well over sharp spikes or sharp edges on components – the coating will be much thinner or even not present in such areas. This phenomenon is known colloquially as edge crawling and is caused by surface tension effects. Obviously solder spikes should be avoided or cropped – components legs fabricated from round cross section wire will cover better than those stamped from flat sheet. Edge crawling can be minimised by careful attention to the viscosity of the conformal coating – also multiple thin coats will give better edge cover than attempting to apply one thick one. Electrolube have developed a special filled conformal coating, DCRT, designed to be applied in coating thicknesses around 100micron – this gives improved edge cover over that obtained with conventional liquid coating resins.

Conformal coatings generally fall into several distinct chemical types. These are as follows:

Acrylic coatings, such as Electrolube’s HPA or APL, almost invariably consist of a solution of a thermoplastic acrylic polymer dissolved in a blend of organic solvents. As such the coating dries by simple solvent evaporation: no cross-linking is involved. This means that acrylic coatings can soften at high temperatures but also they are easily removed with solvent to enable board repair. Usually low boiling solvents are used as the carrier and this leads to rapid touch dry and through dry times. Bath life is very long as solvent that has evaporated can be readily topped up, thus maintaining the target viscosity. The solvents are flammable and this type of coating is coming under pressure because of increasingly restrictive environmental legislation concerning emissions of solvent into the atmosphere. Moisture resistance of this type of coating is good but resistance to organic solvents is relatively poor.

Epoxy coatings are generally very hard, often opaque and posses excellent moisture resistance and chemical resistance generally.

They are usually supplied as two part systems which makes them much less user friendly than other types of coating. The cross-linking nature of this type of coating means that mechanical properties and abrasion resistance are excellent, but the cured coatings are almost impossible to remove from the board. Consequently board repair can become a big problem.

Urethane coatings offer similar properties to epoxies with even better abrasion resistance. Again toughness and moisture and solvent resistance are good but their cross linked nature makes removal and board repair difficult.

Silicones cover rather a wide family of different materials, with a range of differing characteristics and properties. Conventional silicone coatings can vary from tough abrasion resistant materials to soft elastomeric coatings which give rise to very low levels of stress on the boards and their components. Cure can be by either heat cure or RTV (room temperature vulcanising, usually by reaction with atmospheric moisture, leading to cross-linking). Silicone alkyds, such as Electrolube’s DCA, are tough and offer a good balance of properties both from a mechanical, electrical and chemical property point of view – cross linking level is improved by heat curing to obtain maximum solvent and chemical resistance. All silicone coatings are characterised by very good high temperature performance compared with other types of coating.

Other types of specialist coatings have also been developed. UV cure coatings can be cured rapidly in line by exposure to UV lamps – these coatings are especially useful where high volume board production is concerned. Areas under components that are shielded from the UV radiation can be slow to cure, giving rise to the so-called shadow effect. This can be minimised by altering the chemistry to incorporate a secondary curing process, which can involve thermal or moisture cure. In these so-called dual cure systems, there is a rapid initial UV cure in the bulk of the coating, followed by a slower secondary cure in the shadow areas. The chemistry of the UV cure materials limits the performance of the cured coating to some extent – generally properties are not as good as those of the long established solvent based materials.

Water based conformal coatings have been developed in response to increasing environmental pressures against the use of organic solvents. These tend to be rather slow to dry and so-called “mud cracking” can occur with increased coating thicknesses. Again the chemistry of this type of coating can restrict the operational performance of the final cured coating.

There is one very special type of coating process, completely different from all those described above. This is the parylene process developed originally by Union Carbide. A chemical called di-p-xylylene is pyrolyzed at around 650◦C in a high vacuum environment. The resultant monomer polymerizes on to all surfaces present in the high vacuum environment giving a very even pinhole free coating. This process means that boards containing sharp edged components and solder spikes are coated very evenly – all conventional liquid coating processes result, as has been mentioned previously, in considerable thinning of the coating on edges and spikes due to surface tension effects. The parylene process is also very effective at coating the under side of board components where there is a gap between the board and the component. The parylene coating process is, however, as might be anticipated, very expensive when compared to conventional coating processes. Modifications to the chemistry are available leading either to coatings of improved breakdown voltage or, alternatively, to coatings of improved thermal stability.

Various standards exist relating to conformal coatings for printed circuit boards. Some of the more important are IEC 61086-1/2/3, IPC-CC-830 and UL 746E. IPC-CC-830 is derived from, and has now superseded, the old MIL-I-46058. The UK standard DEF-STAN 59-47 is no longer current. It would be appropriate here to discuss some of the more important properties relevant to conformal coatings – these are typical properties, values for which will be found on technical data sheets for conformal coatings. The tests here are taken from the IEC standard – IEC 61086 specifies three classes for conformal coatings with increasingly stringent pass criteria. The classes are general purpose (Class 1), high reliability (Class 2) and aerospace (Class 3).

Breakdown voltage is the voltage at which electrical breakdown occurs between parallel tracks at a standard distance apart on a standard Y test pattern. Insulation resistance is the resistance between two electrodes on a standard test pattern – the electrodes consist of an interleaving comb pattern, where alternate “teeth” on the comb are connected to either the positive or negative electrode. The Y pattern and comb pattern are usually combined on one test board. (see above) Flexibility tests on the coating are carried out by bending a coated copper sheet around a 3mm or 6mm mandrel and checking for any cracking or crazing of the coating. Mould growth tests may be carried out on a coated glass panel. Flammability tests are carried out by coating a test bar of printed circuit board material (usually FR-4) and applying a standard flame at the end. There are laid down pass criteria in terms of burning time after removal of the flame – the maximum allowed distance travelled by the flame is also specified.

Various further environmental exposure tests may be carried out using the standard coated test board containing the Y and comb pattern. These include thermal cycling and thermal shock tests between specified temperatures – visual examination is carried out subsequent to the test to determine that there has been no flaking or delamination of the coating. Damp heat testing is also carried out – subsequent insulation resistance must be greater than 10¬9 ohm and breakdown voltage is also determined and reported. For Class 2 coatings a salt mist test is introduced and for class 3 coatings a cold, low air pressure and damp heat test is introduced.

Some other electrical properties may also be found on technical data sheets for conformal coatings. Dielectric strength is the voltage at which electrical breakdown occurs through the coating film, perpendicular to the plane of the film. Volume resistivity and surface resistivity may also be quoted for the cured coating film. Dielectric constant and loss tangent may also be quoted – a low dielectric constant for the coating material can be important for coating tuned circuits. A high dielectric constant can produce stray unwanted capacitance effects between surface tracks that run close and parallel to one another – this can alter the tuned characteristics of the circuit. Comparative tracking index will give a crude measure of how easily the conformal coating will be subject to failure by electrical tracking – this is usually brought about when high voltages cause surface decomposition of the coating and a conductive carbon path is formed.

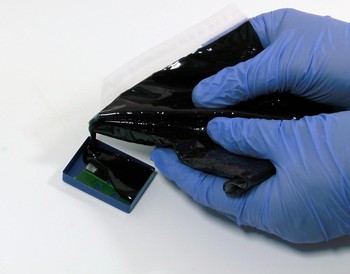

Finally we will consider methods and equipment available for applying conformal coatings. There are many suppliers of dipping equipment used to apply conformal coatings – a wide range of sophistication and prices is available. It is important with dipping to carefully control withdrawal speed as this will determine coating thickness – the slower the withdrawal speed, the thinner will be the resultant coating. Coating thickness will also be determined by other factors such as viscosity, solids content and temperature of the coating solution. Boards are usually dipped vertically, but sophisticated equipment may be able to tilt the board from the vertical at various stages to better achieve the desired coating thickness. There will usually be some areas of the board – e.g. connectors or other electrical contact points – that must not be coated. If these are below the required level of dipping then this will require masking of the board with tape or a peelable coating mask – this is a costly and time consuming operation.

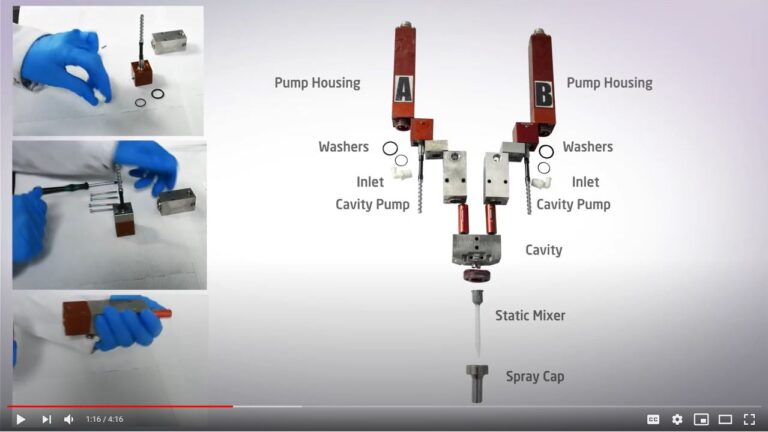

Spraying equipment has seen increasing development over recent years. It is now possible to spray the board in the required areas only, thus obviating the need for masking. Development has led on to film coating and swirl coating, resulting in capability of handling a wider range of viscosities and increasing precision of the coating operation. Combination of this type of coating equipment with a UV cure line or infra red ovens enables high speed production of complex coated boards.

What does the future hold for conformal coatings? At present, it is difficult to match the performance of the long established solvent based conformal coatings with newer technologies. We anticipate that there will be increasing environmental pressures against the release of organic solvents into the atmosphere, with the consequent effect on global warming and general environmental pollution and smog formation. [An article summarising the requirements of the latest European Solvent Emissions Directive is available from Electrolube on request.] These environmental pressures will necessitate both increasing measures to trap and recover released solvent and also further development of UV cure and water based coatings to raise their performance closer to that of the more traditional solvent based materials. We will also see further steps to develop both high solids and, ultimately, solvent free coatings.