Make it with our expertise

LED Protection Solutions

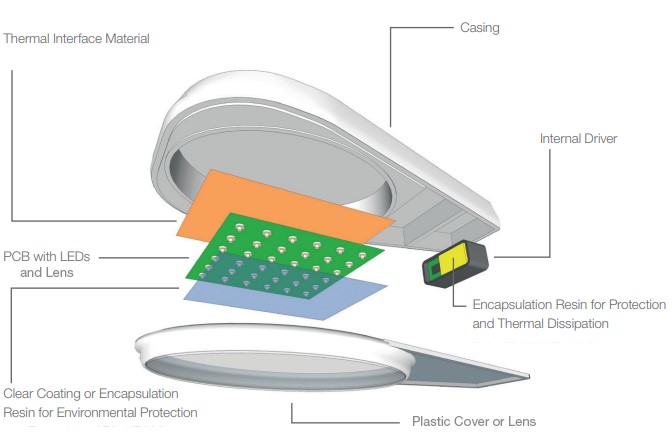

As the LED Luminaire Industry expands, LEDs are being used in ever more challenging environments and thus need adequate protection from exposure in a vast variety of environments. In addition to casing and covers, many LED manufacturers are choosing to encapsulate or coat the LED – or even to pot the entire unit in order to protect the luminaires.

Thermal management is also a vital consideration for an LED. With a single degree centigrade of heat having such a large effect on the colour, efficiency and the lifetime of an LED Luminaire, the thermal interface material chosen for the LED design is of vital importance.

Electrolube have a specialist LED brochure providing comparisons and test data to help you chose the right product for your application; this includes a wealth of useful information such as collaborative test data from Bridgelux comparing data on Conformal Coatings vs Encapsulation resins, Absolute Colour Change (∆E*ab) following 1000 hours UV Exposure, the difference potting depth makes and general product comparisons to help you make the right choice.

-

Conformal

Coatings -

Encapsulation

Resins -

Thermal

Management -

Contact

Lubricants -

Electronic

& General Cleaning -

Maintenance

& Service Aids

- Environmental Protection for LEDs

- Thermal Management of LEDs

- LED Driver Protection

- Switch + Control Lubricants

- Sensor Protection

If you have any questions our dedicated technical support team are also on hand to answer your questions and we also have a wealth of information available in our Technical Articles and Blogs section:

Make it our problem

Electrolube has been at the forefront of the LED boom, supplying specialist solutions to the world’s best known LED manufacturers. Electrolube materials work to protect components and prolong the life of LED units and their associated components such as drivers.

Electrolube's extensive range of specialist products developed specifically for the LED industry include conformal coatings, encapsulation resins and thermal management materials.

Find your Electrolube Solution.

Problem

Street light application

External LED street lighting application. LEDs were protected by lens and casing but moisture was still getting in and affecting the PCB causing corrosion.

Solution

AFA provided as an alternative to a resin to coat the entire PCB and Luminaire including the lens. Optical clarity maintained while the coating provided moisture protection.

Problem

Automotive Lighting

External lighting on a commercial vehicle required protection from chemicals, salt mist and other external factors due to its exposure to road conditions.

Solution

UR5634 was selected due to its optical clarity, maintaining the colour of the LED after prolonged exposure while offering the protection required in the harsh conditions.

Problem

Underwater Swimming Pool Light

LED spotlights installed under swimming pools required thermal management material that would dissipate heat out to the casing.

Solution

ER2074 was selected as a highly thermally conductive resin that acted both as a thermal management material, whilst also protecting the PCB from possible chemical or moisture ingress due to being under the swimming pool. ER2074 also has a white finish which was preferable for aesthetic reasons.

Problem

Commercial vehicle lights

Competitor product was proving hard to apply and not performing to expected standards.

Solution

HTSP was selected providing significant performance improvement vs the current material as well as offering an improved application process to streamline production.

Make it with a tailored solution

If our range does not quite meet what you are looking for, our technical support and research and development teams will work with you to solve your chemical problem and supply the perfect solution.