MacDermid Alpha Electronics Solutions, a global supplier of integrated solutions from our Circuitry, Assembly and Semiconductor divisions that provides unmatched capabilities in electronics design and manufacturing, has successfully implemented an efficient thermal management solution for a 5G application in China. Electrolube, part of MacDermid Alpha Electronics Solutions, was approached with a complex thermal management challenge for a base station design that could offer high thermal conductivity and long-term reliability.

5G base stations rely on advanced antenna technology in the form of massive MIMO antennas, which send and receive more data simultaneously over a wider mobile spectrum, referred to as mmWave frequencies. Despite being referred to as ‘massive’, these antennas are similar in size to the 4G antennas. Thus, 5G technology offers increased efficiency without increasing physical size; an ongoing trend in the electronics industry that is closely linked to the rapid growth in the efficient use of thermal management materials. Whilst increases in energy efficiency for data transfer are realised, the power consumption of 5G base stations is much higher than that of a 4G station, again highlighting the need for effective heat dissipation to avoid overheating. Thermal management is a critical element of 5G reliability and performance, and heat dissipation requirements need to be considered at the design phase.

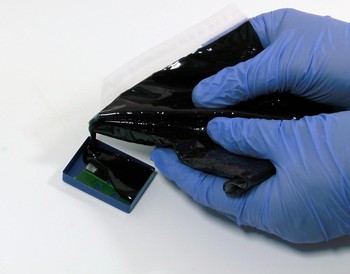

Electrolube’s GF400 gap filler was found to be a highly successful thermal interface material to reduce heat in a multifaceted 5G base station unit design. GF400 is a material that is designed for use with higher thickness than a standard thermal interface material. It provides excellent thermal conductivity but also maintains its stability at these higher thicknesses, ensuring efficient and reliable heat transfer. The base band unit is a critical part of processing baseband signals, increasing capacity and reducing latency. At high temperatures, electromigration also occurs at a faster rate, noise is more intense, embedded antennas radiate less strongly at the desired frequencies, and a multitude of other problems arise in 5G systems. Solutions to these challenges must be addressed at the board level and through the use of thermal management solutions.

Electrolube’s GF400 is a two part, liquid silicone based gap filler that provides excellent thermal performance (4.0 W/m-K). With a wide operating temperature range between -50 to +200°C and non-flammable,GF400 is a dispensible material that can be applied to help dissipate heat from complex geometries. After curing, it forms a low modulus elastomer that can also relieve CTE stress during power cycling. The properties of GF400 make it one of the highest performing thermal management products for managing heat dissipation in data and telecom network applications. The advantages of GF400 showed a lower coefficient of expansion, lower modulus, better long-term reliability and improved cost performance, pushing it to the forefront of thermal management offerings for the connected world.